Mining Feature: MSHA Media Event Highlights Mine Rescue Capabilities

Friday, January 06, 2017

NIOSH Technologies Among Offerings

Outgoing Assistant Secretary of Labor for Mine Safety and Health (MSHA), Joseph A. Main, and MSHA staff showcased the many improvements to mine rescue tools and technologies the agency has deployed at a media event Jan. 5, 2017, held at MSHA's Pittsburgh campus, which is shared with NIOSH's Pittsburgh Mining Research Division and National Personal Protective Technology Laboratory.

Acknowledging the many advances in mine rescue and the historic low number of 25 U.S. mining deaths during 2016, Main cautioned those gathered at the event to stay vigilant and continue to strive for the day when mining fatalities are rare or even nonexistent.

"We cannot be lulled into believing that the era of mine disasters and emergencies is over," he said. "We have more work to do."

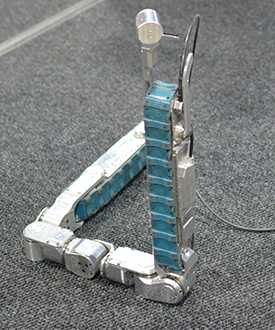

Prominently displayed at the event were two NIOSH-funded rescue robots: the Gemini-Scout Mine Rescue Vehicle, a track-mounted, nimble, and responsive motorized machine loaded with multiple cameras, gas sensors, and two-way voice communication; and the Sarcos Snake Robot, a fully articulating, tandem-track robot fitted with sensors, cameras, and two-way voice communication that is capable of being lowered into a mine via a 4-inch diameter borehole on the surface.

The robots are meant to be used in the event of a mine disaster when it may be unsafe to send in human rescuers. Information from the robots’ sensors can also be used to signal when humans can safely enter the mine. These purpose-built, highly complex robots are currently the property of NIOSH, but will soon be transferred to MSHA.

NIOSH conducts extensive research into disaster prevention, survival, and response. Results of this research include strategies to prevent explosions, systems to prevent rock falls and cave-ins, a computer program that helps design stable mine structures, monitors that precisely measure combustible dusts and gases, training to assist decision-making in emergency situations, best practice guides on using refuge alternatives, and dozens more ways to monitor, measure, and gauge the safety of underground mining.

See Also

- Best Practices and Bolting Machine Innovations for Roof Screening

- BG 4 Benching Trainer Software - 1.0.5

- The Effects of Disaster on Workers: A Study of Burnout in Investigators of Serious Accidents and Fatalities in the U.S. Mining Industry

- Guidelines for Permitting, Construction, and Monitoring of Retention Bulkheads in Underground Coal Mines

- HazComWriter - 3.1.3

- How to use the Coal Dust Explosibility Meter

- NIOSH Mining Update - New Publications 1995-96

- Performance of a Light-scattering Dust Monitor in Underground Mines

- Recommendations for Refuge Chamber Operations Training

- S-Pillar - Software for Stone Mine Pillar Design - 1.02

- Technology News 469 - Sensors Warn of Hazards During Mine Hoisting

- When Do You Take Refuge? Decisionmaking During Mine Emergency Escape

- Page last reviewed: 1/11/2017

- Page last updated: 1/11/2017

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir