Mining Feature: NIOSH OMSHR at the 2015 SME Annual Meeting

On This Page

Friday, February 13, 2015

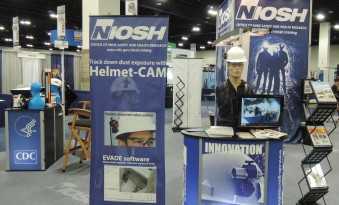

NIOSH will showcase some of its latest mine safety and health innovations at the 2015 Society for Mining, Metallurgy & Exploration (SME) Annual Conference and Expo February 15–18 in Denver, Colorado. Stop by the NIOSH exhibit to see technology demonstrations, pick up one of our latest publications, or talk with our researchers and representatives.

This year’s exhibit features include:

This year’s exhibit features include:

- Collapsible drill steel enclosures (CDSEs). Two drill steels with CDSEs attached will allow visitors to see this new noise-reducing technology for roof bolter machines. This CDSE is a redesign of an earlier NIOSH prototype. In lab testing, this CDSE reduced noise by 3–5 dB and shows improved usability and durability underground.

- Education on black lung disease. Visitors will be able to see X-rays comparing healthy lungs to those that have experienced years of exposure to coal dust, as well as learn more about black lung prevention and detection through NIOSH’s Enhanced Coal Workers' Health Surveillance Program.

- Fiber optic mine atmosphere monitoring. This display will showcase a fiber optic temperature and methane sensor recently tested and adapted for use in underground mining. With modifications to account for rock dust exposure, the sensors were successfully tested in an underground mine for six months.

Helmet-CAM and EVADE software. The Helmet-CAM technology is an innovative personal assessment tool that involves a worker wearing a small video camera and a real-time respirable dust monitor to record worker activities while collecting dust exposure data. The EVADE software merges the video file and dust data so users can identify sources of elevated dust exposure. The Helmet-CAM system and EVADE software will be displayed together so visitors can see how the video and dust data are used in the software, as well as learn how this technology can help them control potentially high dust exposures to their workers.

Helmet-CAM and EVADE software. The Helmet-CAM technology is an innovative personal assessment tool that involves a worker wearing a small video camera and a real-time respirable dust monitor to record worker activities while collecting dust exposure data. The EVADE software merges the video file and dust data so users can identify sources of elevated dust exposure. The Helmet-CAM system and EVADE software will be displayed together so visitors can see how the video and dust data are used in the software, as well as learn how this technology can help them control potentially high dust exposures to their workers.- Hydrophobic rock dust. Visitors will be able to compare traditional rock dust with hydrophobic rock dust, which has an additive that prevents caking when the dust is exposed to water and dried. Video at the display will show the differences in dispersibility between the two types of rock dust. OMSHR researchers will continue to study hydrophobic rock dust for future use in mines.

- New developments in breathing air supplies. Visitors will be able to see prototypes of docking/switchover valves, which allow for continued breathing protection when switching to a new unit; a hood mask with a speech diaphragm, which offers increased face protection and allows users to speak while wearing the device; and very high-pressure cylinders, which provide more efficient oxygen storage.

- Refuge alternative temperature assessment research. Visitors will see 3D-printed models showing the results of tests and simulations where OMSHR studied how the temperature in a refuge alternative rises due to heat generated by various sources, including CO2 scrubbers and miners’ bodies. These results can be used to guide development of future refuge alternative technologies.

NIOSH Presenters

NIOSH will be presenting in a variety of technical sessions throughout the meeting. Be sure to attend these sessions and hear even more about NIOSH’s work in mine safety and health.

| Date | Session | Title | Time/Room | NIOSH Speakers |

|

Monday, February 16 |

Coal & Energy: The Best of Ground Control |

Calibration and Application of Photogrammetric Monitoring of Rock Mass Behavior in Underground Mining |

3:25 pm |

Donovan Benton |

|

Tuesday, February 17 |

Mining & Exploration: Technology: Technology Development and Implementation in Rock Mechanics and Ground Control |

A New High Force and Displacement Shotcrete Test |

9:05 am |

Brad Seymour |

|

Coal & Energy: Underground Mining Processes and Practices |

Roof and Pillar Failure Associated with Weak Floor at a Limestone Mine |

9:05 am |

Michael Murphy |

|

|

Coal & Energy: Mining Research and Development |

Determination of the Fire Hazards of Mine Materials Using a Radiant Panel |

10:35 am |

Sam Harteis |

|

|

Coal & Energy: Mining Research and Development |

MulsimNL/Large: Reviving A USBM Tool for Modeling Western Mines |

10:53 am |

Mark K. Larson |

|

|

Coal & Energy: Dust Control I |

Laboratory Assessment of a Tailgate Spray Manifold to Reduce Dust Exposures for Shearer Face Personnel |

2:25 pm |

James Rider |

|

|

Coal & Energy: Dust Control I |

Influence of Continuous Mining Arrangements on Respirable Dust Exposures |

2:45 pm |

Timothy Beck and W. Randy Reed |

|

|

Coal & Energy: Breathing Air Supplies I |

Next Generation Breathing Air Supplies Status |

2:25 pm |

Rohan Fernando |

|

|

Coal & Energy: Breathing Air Supplies I |

SCBA Filling from Auto-Cascading Air Refill Stations |

4:05 pm |

Rohan Fernando |

|

|

Industrial Minerals and Aggregates: Health & Safety |

A Useful Tool for Predicting the Occupational Hearing Loss in Mining Industry |

3:05 pm |

MingFeng Li |

|

|

Coal & Energy: Developments in Health and Safety |

Underground Field Tests of Second-Generation Proximity Detection Systems on Continuous Mining Machines |

3:05 pm |

Jacob Carr |

|

|

Research: NORA Safety and Health Research for Small Mines |

The Health of Workers in Small Underground Coal Mines |

3:45 pm |

Alice Shumate |

|

|

Wednesday, February 18 |

Mining & Exploration: Technology: Electronic Safety Technologies |

Field Evaluation of Wireless Machine Guard Monitoring System |

2:05 pm |

Miguel Reyes |

|

Mining & Exploration: Technology: Electronic Safety Technologies |

Proximity Detection with Selective Machine Shutdown |

2:45 pm |

Joseph DuCarme and Jacob Carr |

|

|

Mining & Exploration: Technology: Electronic Safety Technologies |

Integrating Technology: Learning from Mineworker Perceptions of Proximity Detection Systems |

3:05 pm |

Emily Haas |

|

|

Coal & Energy: Dust Control II |

Field Evaluation of an Inline Wet Scrubber for Reducing Float Coal Dust on a Continuous Miner Section |

2:45 pm |

Jay Colinet |

|

|

Coal & Energy: Ventilation Innovations II

|

CFD Analysis on Gas Distrbution for Different Scrubber Redirection Configurations in Sump Cut |

3:25 pm |

David Zheng, Timothy Beck, and James Rider |

See Also

- Breathing Air Supplies and Refuge Alternative Research at SME 2016

- Coal Dust Explosibility Meter Evaluation and Recommendations for Application

- Cryogenic Life Support Technology Development Project

- Hearing Loss Prevention in Mining - 2005

- How to Operate a Refuge Chamber: A Quick Start Guide

- I Can't Get Enough Air! Proper Self-contained Self-rescuer Usage

- Recommendations for Refuge Chamber Operations Training

- Refuge Alternatives in Underground Coal Mines

- Refuge Chamber Expectations Training - 1.0

- Technology News 536 - NIOSH Develops New Software to Analyze and Reduce Noise Exposure

- Page last reviewed: 2/17/2015

- Page last updated: 2/17/2015

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir