Mining Feature: Deep Metal Mine Fatality Raises Questions on Use of Cemented Fill

Sunday, May 20, 2012

In light of recent accidents in metal mines, some fatal, NIOSH's Office of Mine Safety and Health Research (OMSHR) is again studying the use of cemented fill in mining operations.

Just last month, a miner was fatally injured at the Lucky Friday silver mine in North Idaho when the cemented fill materials in more than 70 ft of a mined area collapsed. Other fatalities, one each in 2007 and 2008, were related to using cemented fill to stabilize underground metal mine openings.

OMSHR researchers will examine the contributing factors to cemented fill failures to determine if the current cemented fill design and installation practices are adequate for conditions found in modern U.S. metal mines. If areas are identified where applied research could improve mine safety, a research proposal will be initiated.

Metal Mining Methods

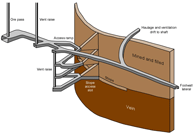

Underground metal mines in the U.S. use a variety of mining methods to extract ore. The mining method selected is based on the nature of the ore body, depth of underground deposit, and the strength of the ore and surrounding rock. Precious metal mines that extract gold and silver are often found in vein-type deposits where the ore is concentrated in narrow, steeply pitching deposits along zones of weakness in the host rock. In underground metal mines, the area where ore is extracted is known as a stope.

When mining gold and silver veins at great depth or in very weak rock, operators need to minimize the amount of exposed ground in the tunnels or drifts. This can be done by filling areas where the ore has been extracted with an engineered mixture of waste rock, aggregates, and cement, known as cemented fill. This fill material allows adjacent sections to be subsequently mined.

Where ground is very weak or where depth is so great that strong rocks have the potential to burst (fail violently), the mined cuts of ore extracted underneath the fill can actually be made safer than the original host rock. Then miners install supplemental support - rock bolts, wire mesh, shotcrete - to further protect themselves from the potential for falling ground in these stopes.

Over the last several decades, the use of cemented fill to stabilize underground metal mine openings has significantly improved safety in metal mines. However, the recent fatalities in these cemented fill areas are driving fresh attention to these practices

NIOSH OMSHR related links

- Geomechanics of Reinforced Cemented Backfill in an Underhand Stope at the Lucky Friday Mine, Mullan, Idaho

- Underhand Cut and Fill Mining as Practiced in Three Deep Hard Rock Mines in the United States

- Determination of In Situ Deformation Modulus for Cemented Rockfill

- Rock Mechanics Investigations at the Lucky Friday Mine

MSHA Investigation Reports

See Also

- Characteristics of the Top Five Most Frequent Injuries in United States Mining Operations, 2003-2007

- Historical Mine Disasters

- Independent Contractor Trends in the United States Mining Industry

- Major Disasters at Metal and Nonmetal Mines and Quarries in the United States (Excluding Coal Mines)

- Metal/Nonmetal Mining Disasters: 1869 to Present

- MSHA Data File Downloads

- NIOSH Mining Update - New Publications 1995-96

- Performance of a Light-scattering Dust Monitor in Underground Mines

- Technology News 491 - NIOSH Releases Two New Safety Training Videos

- Technology News 501 - Measuring Very Low Air Velocities in Underground Metal/Nonmetal Mines

- Page last reviewed: 4/10/2014

- Page last updated: 9/28/2012

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir