Mining Topic: Spontaneous Combustion

What is the health and safety problem?

Spontaneous combustion continues to pose a hazard for U.S. underground coal mines, particularly in western mines where the coal is generally of lower rank. The risk of an explosion ignited by a spontaneous combustion fire is also present in those mines with appreciable levels of accumulated methane.

What is the extent of the problem?

Approximately 15% of the 164 total reported fires for underground coal mines for the period 1978–1990 were caused by spontaneous combustion. For the period 1990–2006, more than 20 U.S. coal mines suffered underground spontaneous combustion events, and 25 total reported fires for underground coal mines were caused by spontaneous combustion. The incidence of spontaneous combustion fires and the resulting explosion hazard in underground coal mines is expected to increase with the projected increased mining of lower rank coals, deeper mines with more methane, and the growth in the dimensions of longwall panels.

How is the NIOSH Mining program addressing this problem?

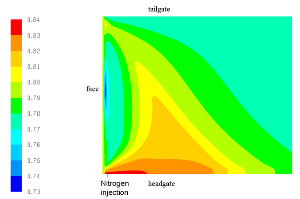

Nitrogen concentration distribution in the gob after 20 days with a nitrogen injection rate of 500 cfm (1=100%).

The Office of Mine Safety and Health Research (OMSHR) conducted research to reduce spontaneous combustion risk in underground coal mines through the development of control methods and nitrogen injection strategies to prevent spontaneous heatings. The control methods include: (1) Optimizing the ventilation system to eliminate the possible critical velocity zones where the spontaneous heating will likely occur; (2) Selecting an appropriate face advance rate to prevent the coal oxidation behind the shields not to reach a thermal runaway; (3) Early detecting of spontaneous heating to allow for enough time to suppress the heating.

What are the significant findings?

OMSHR research has developed a computational fluid dynamics (CFD) model that can be used to simulate spontaneous heating of coal in the longwall gob area under realistic mine ventilation conditions and methane generation rates. The critical velocity zones for spontaneous combustion in the longwall gob area were identified for different gob conditions and coal properties based on the CFD simulations. The research also investigated the effects of longwall face advance rate, gob seal leakage, and the barometric pressure changes on the spontaneous combustion process in these longwall gob areas. The research results can help mine ventilation engineers and mine safety personnel better prevent and control spontaneous combustion.

OMSHR conducted CFD modeling to develop strategies for nitrogen injection for underground coal mines using bleeder or bleederless ventilation systems to prevent the spontaneous heating of coal. Guidelines for injection location and flow rates using nitrogen were developed. Research was also conducted to determine the optimal sampling locations for early detection of spontaneous combustion in longwall gob area.

See Also

- CFD Modeling of Spontaneous Heating in a Large-Scale Coal Chamber

- CO and CO2 Emissions from Spontaneous Heating of Coal Under Different Ventilation Rates

- Computational Fluid Dynamics Modeling of Spontaneous Heating in Longwall Gob Areas

- Effect of Longwall Face Advance on Spontaneous Heating in Longwall Gob Areas

- The Effect of Ventilation on Spontaneous Heating of Coal

- Effects of Ventilation and Gob Characteristics on Spontaneous Heating in Longwall Gob Areas

- Modeling the Effect of Barometric Pressure Changes on Spontaneous Heating in Bleederless Longwall Panels

- Modeling the Effect of Seal Leakage on Spontaneous Heating in a Longwall Gob Area

- Numerical Study on Effects of Coal Properties on Spontaneous Heating in Longwall Gob Areas

- Proceedings of the International Workshop on Rock Mass Classification in Underground Mining

- Simulation of Spontaneous Heating in Longwall Gob Area with a Bleederless Ventilation System

- SPONCOM - A Computer Program for the Prediction of the Spontaneous Combustion Potential of an Underground Coal Mine

- SponCom - Spontaneous Combustion Assessment Software - 2.0

- Technology News 545 - NIOSH Updates Spontaneous Combustion Assessment Software

- Page last reviewed: 4/7/2017

- Page last updated: 4/7/2017

- Content source: National Institute for Occupational Safety and Health, Mining Program

ShareCompartir

ShareCompartir