COMMERCIAL FISHING SAFETY

Engineering Interventions

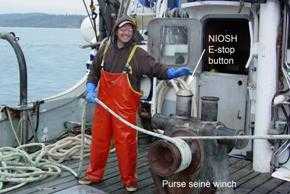

NIOSH’s fishing safety engineering program began in 2004 when engineers at the NIOSH Spokane Research Laboratory partnered with epidemiologists from the NIOSH Alaska Pacific Office to address deck safety among purse seiners in Alaska. Injury and fatality data analysis pointed to contact injuries as the leading cause of non-fatal traumatic injuries among commercial fishermen in Alaska. Further focus groups with fishermen identified the hydraulic capstan winch on purse seiners as the piece of machinery with the most potential for career-ending injuries. Addressing this issue through the development of an emergency stop system for hydraulic capstan winches would be the first in a series of fisherman-focused engineering interventions conducted by NIOSH.

E-Stop for Capstan Winches

NIOSH prototype E-Stop being tested on the Purse seiner F/V Lake Bay

NIOSH researchers and engineers worked with purse seine fishermen on the design and testing of an emergency stop (e-stop) switch that stops the deck winch if someone becomes entangled. The e-stop system allows the winch to be stopped by a worker, even if the worker is caught in the winch. The system was successfully tested on vessels during the 2005-2007 fishing seasons and is now commercially available as a retrofit-kit from Kolstrand Marine. In a major success story for NIOSH’s Research to Practice initiative, all three major capstan winch manufacturers in the Northwest now provide E-Stops as standard features on their new seine winches. For more details refer to the article “Reducing Commercial Fishing Deck Hazards with Engineering Solutions for Winch Design.” Watch The Most Powerful Thing, a NIOSH safety awareness DVD designed to help crew members be more aware of safety hazards on-board purse seining vessels. The DVD highlights interviews with fishermen, and the e-stop solution to prevent injuries that occur as a result of getting entangled in the winch.

Hatch and Door Monitoring System

Prototype Hatch/Door Monitor Display

NIOSH developed a hatch and door monitoring system for commercial fishing vessels that is inexpensive, easy to install, robust, and able to be retrofitted on existing vessels. NIOSH engineers installed and evaluated the system on two fishing vessels, F/V Lilli Ann and F/V Gladiator, which are working in Alaskan waters. In 2012, the system was licensed to Oregon-based Wapato Engineering to produce and market the commercial version of the monitoring system.

Flood-Rate Monitoring System

Second generation prototype using programmable virtual meters for the display monitoring three tanks.

Two contributing factors in many vessel disasters is the uncontrolled flooding of watertight compartments and the free-surface effect of partially filled holds. Most flood alarms found in commercial fishing boats prompt pumps to operate, but do not indicate the status of the flooding. They do not tell if the pumps are keeping up with the in-rush of water. NIOSH engineers have developed a Flood-Rate Monitor that not only triggers the pumps, but also shows the relative flood level and the rate of its increase or decrease. In function, it tells whether the pumps are gaining, maintaining, or failing to keep up with the flooding. This information is sent to the wheelhouse for the captain and crew to respond to the risk.

A variant of the Flood-Rate Monitor, called the Slack-Tank Monitor, was developed after NIOSH engineers were alerted by fishermen that traditional float-style switches used to sense tank levels were unreliable due to their propensity to get clogged with debris. A fish hold or tank that is not completely full or empty is referred to as a “slack tank” and dangerously reduces a ship’s stability due to the "free surface effect", a condition where water can slosh back and forth in a confined space. A Slack-Tank Monitor using pressure transducers to sense tank levels was designed to reduce the chances of mechanical failure due to fouling from machine oil, grease, fish slime, or debris. The first prototype version Slack-Tank Monitor System was installed on the F/V Epic Explorer in January 2011 for testing in the Bering Sea. The second prototype design, using virtual meter displays, was installed on the F/V Bristol Explorer and replaced the initial test system on the F/V Epic Explorer (F/V Alaska Endeavor) in the fall of 2011. The design of the Slack-Tank Monitor is similar to the Flood-Rate Monitor. Sea-test results for the Slack-Tank Monitor will also be indicative of the robustness of the Flood-Rate Monitor.

Preventing Winch Entanglements among Shrimp Fishermen in the Gulf of Mexico

In 2012, a 15-year-old deckhand on a shrimp trawler in the Gulf of Mexico lost his life after getting entangled in a winch. At the request of the US Coast Guard, NIOSH reviewed data from the Commercial Fishing Incident Database as well as US Coast Guard investigative reports to understand the risk factors associated with winch entanglements in this fishing fleet.

From 2000-2011, 35 injuries (8 fatal) involving winches were reported in the shrimp fleet fishing Gulf of Mexico waters. Injuries involving the main winch drums had a higher risk for fatal outcomes compared to injuries involving the winch cathead. Injuries were often fatal, where nonfatal injuries were usually severe and disabling. These results can be found in greater detail in the published CDC MMWR, “Fatal and Nonfatal Injuries Involving Fishing Vessel Winches — Southern Shrimp Fleet, United States, 2000–2011”.

NIOSH is currently addressing the unique entanglement hazards on shrimp vessels by developing static winch guards for the mechanically-drive main drum winches and an Auxiliary Stop (A-Stop) for the electric “try-net” winch. For more information on the current status of the project, or if you are interested in partnering with NIOSH to help test these solutions, please read our Reducing Winch Entanglements with Stationary Guarding or Reducing Winch Entanglements with Auxiliary-stop Device fact sheets for the latest project and contact information.

Static Guarding of Drum Winches

NIOSH researchers conducted a series of site visits to ports around the Gulf of Mexico to determine the main areas of concern related to winch operations on shrimp vessels. After discussions with US Coast Guard staff, vessel owners, shrimp fishermen, and winch manufacturers, they identified four main activities that lead to winch entanglements on shrimp vessels: line leveling, retrieving wire rope, working the catheads, and operating the try-net winch.

Further research identified the three most common type of drum winches used around the Gulf of Mexico and the NIOSH engineers developed static guards for each of the three types. These three prototypes are now being tested on vessels throughout the Gul of Mexico and feedback on their performance is being used to develop improvements to each design.

505 McElroy-Catchot winch before static guard installation

505 McElroy-Catchot winch after guard installation

Auxiliary Stop for Try-net Winches

Auxillary Stop switch installed on try-net winch

Try-net winches are small, electric-driven winches with a drum and exposed cathead used to pull in a small “try-net” to see if the vessel is still trawling along in the shrimp. The controls for this winch are usually located on the boat’s house roof, so they are accessible to fishermen standing away from the winch, but now within easy reach while operating the winch. In the event of an entanglement, a fisherman cannot reach the controls to stop the winch.

NIOSH engineers have developed an Auxiliary Stop system with buttons mounted directly on the winch housing. These ribbon-style switches can easily be reached by a fisherman entangled in the winch drum or cathead and disengage the motor, lessening the severity of the potential injury.

Locations of NIOSH test vessels in the Gulf of Mexico

- Page last reviewed: June 8, 2015

- Page last updated: June 8, 2015

- Content source:

- National Institute for Occupational Safety and Health Office of the Director

ShareCompartir

ShareCompartir